When it comes to 3D printing, the first and most crucial decision you'll make is choosing the right printer. With so many options available in the market, it can be overwhelming to figure out which one will best suit your needs. To make this process easier for you, we've compiled a list of factors to consider when selecting a 3D printer.

Firstly, consider the size of the objects you're planning to print. Different printers have different build volumes, which impacts the maximum dimensions of the objects you can print. If you intend to print small trinkets or prototypes, a compact printer will suffice. However, if you plan to print larger items or want to print multiple objects simultaneously, you'll need a printer with a larger build volume.

Secondly, think about the level of 3D printing experience you have or your willingness to learn. Some printers are more user-friendly and require minimal tinkering, making them suitable for beginners. On the other hand, if you're an experienced user or eager to dive into the technicalities, a printer with more advanced features and customization options might be the right fit.

Lastly, consider your budget. 3D printers range in price from a couple of hundred dollars to thousands of dollars. Determine how much you're willing to invest and what features are essential for you. Keep in mind that while a higher-priced printer may offer better quality and advanced features, there are also plenty of affordable options that can still deliver impressive results.

Essential Materials and Tools for Successful Printing

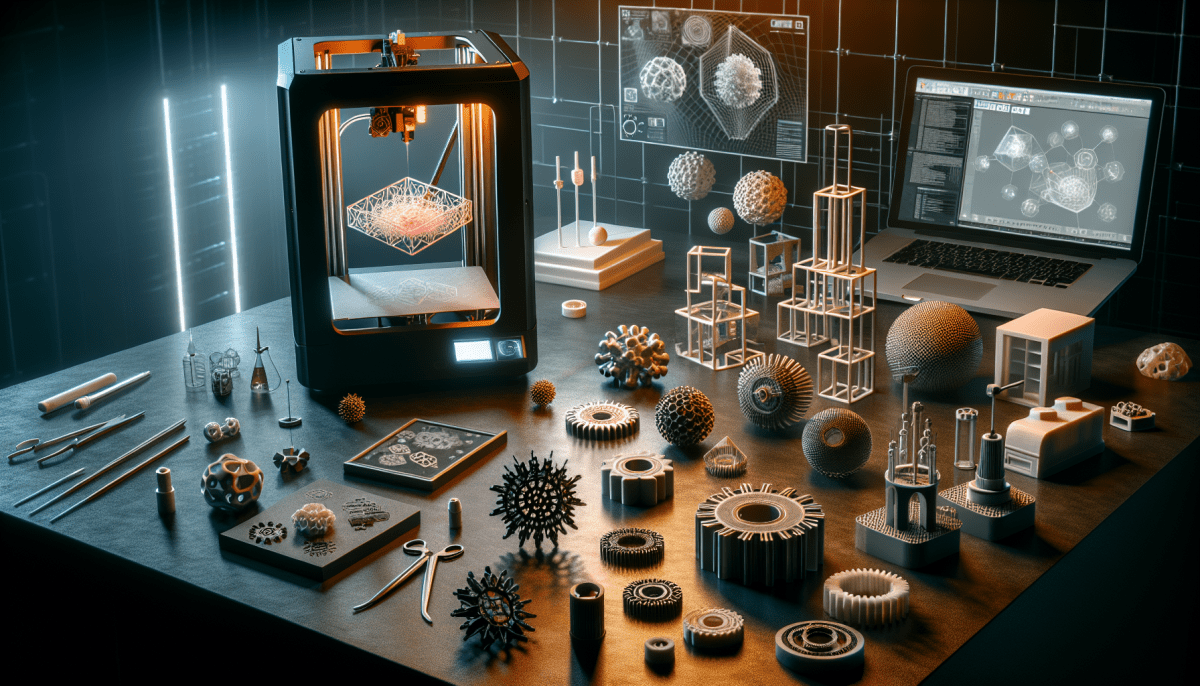

When it comes to mastering 3D printing, having the right materials and tools at your disposal is crucial to ensuring successful prints every time. Whether you're a beginner or a seasoned expert, having a well-stocked arsenal of essentials will make all the difference in the quality and precision of your prints.

One of the most important materials for 3D printing is filament. Available in various materials such as PLA, ABS, and PETG, filament is the plastic thread that is melted and extruded to build your print layer by layer. Different filaments have different strengths and applications, so it's important to choose the right one for your project. Additionally, having a quality filament storage solution is essential to prevent moisture absorption, which can lead to print failures and compromised print quality.

Next, let's talk about the tools you'll need to have on hand. To start, a good pair of needle-nose pliers will prove invaluable when it comes to removing support structures and fine-tuning your prints. A set of precision tweezers is also a must-have for delicate tasks such as filament changes and print cleanup. Additionally, investing in a quality scraper or spatula will make it easier to remove prints from the build plate without damaging the surface.

Lastly, don't forget about maintenance and calibration tools. Keeping your 3D printer in optimal condition requires regular maintenance, such as lubricating moving parts and checking belt tension. To aid in this, having a set of precision screwdrivers and a caliper for measuring part dimensions is essential. By ensuring your printer is properly maintained and calibrated, you'll be able to consistently achieve high-quality prints.

Understanding the Basics of 3D Modeling

When it comes to mastering 3D printing, understanding the basics of 3D modeling is crucial. 3D modeling is the process of creating a digital representation of an object or a design using specialized software. It is the foundation of any 3D printing project, as it allows you to design and create the objects you want to print. Whether you're a newbie or a seasoned enthusiast, knowing the basics of 3D modeling will significantly enhance your 3D printing experience.

One of the first things you need to know about 3D modeling is that it involves working with three dimensions: length, width, and height. Unlike 2D modeling, which only deals with two dimensions, 3D modeling adds another crucial dimension, making it possible to create realistic and complex designs. Understanding how to manipulate these dimensions will allow you to create precise and intricate 3D models.

In addition to dimensions, 3D modeling also involves shapes and objects. By combining various shapes, such as cubes, spheres, and cylinders, you can create more complex geometries. Understanding how to create and manipulate these shapes using software tools will unlock endless possibilities for your 3D printing projects.

Lastly, understanding the concept of parametric 3D modeling is essential for creating reusable and customizable designs. With parametric modeling, you can create objects that can be easily modified by adjusting specific parameters, such as size, shape, or dimensions. This feature is especially useful when you want to create variations of a design or make adjustments to fit specific requirements.

Troubleshooting Common Problems in 3D Printing

3D printing is an amazing technology that offers endless possibilities for creators, but it can sometimes be frustrating when things don't go as planned. To help you become a master of 3D printing, here are some essential tips for troubleshooting common problems:

1. Print Quality Issues

If you notice that your prints have rough surfaces, inconsistent layers, or poor adhesion, the first thing to check is your printer's calibration. Make sure the bed is leveled and the nozzle height is correctly set. Filament issues can also affect print quality. Check that the filament diameter matches the settings in your slicing software, and ensure it is properly loaded and not tangled. Experimenting with different print speeds and temperatures can also improve quality.

2. Extrusion Problems

Extrusion problems can result in under-extrusion (when the layers are not bonded properly) or over-extrusion (causing messy prints). To fix under-extrusion, check if the filament is tightly gripping the gear and flowing smoothly through the nozzle. Clear any obstructions that may be blocking the filament path. Over-extrusion can be resolved by adjusting the extrusion multiplier in your slicing software or reducing the flow rate. Fine-tuning these settings can greatly improve the extrusion process.

3. Warping and Adhesion Troubles

Warping occurs when the corners of your print start to curl up. This issue is often caused by inadequate bed adhesion or temperature differences between layers. Applying a heated bed, using a build surface like painter's tape or a glass bed with adhesive, and applying a brim or raft can help prevent warping. Additionally, adjusting the print bed temperature and using a suitable adhesive such as glue stick or hairspray can enhance adhesion success.

Remember, troubleshooting is part of the learning process. Patience and experimentation are keys to mastering 3D printing. By addressing these common problems, you'll be well on your way to creating high-quality prints and pushing the boundaries of your imagination!